|

So, you snapped that new hex tool tip getting the above screw out of your car? Then you had to use a rotary tool to slot it, ruining that chassis in the process... I wonder why? The proper application of thread locking compound is not difficult, but it is easy to over do. First, ensure you are using the correctly rated thread compound. For most RC applications, "permanent" (often red), is almost never used. This is on par with spot welding, true the screw will never move, but removing it in the future for maintenance might prove impossible. For most RC applications, "temporary" (often blue) is used.

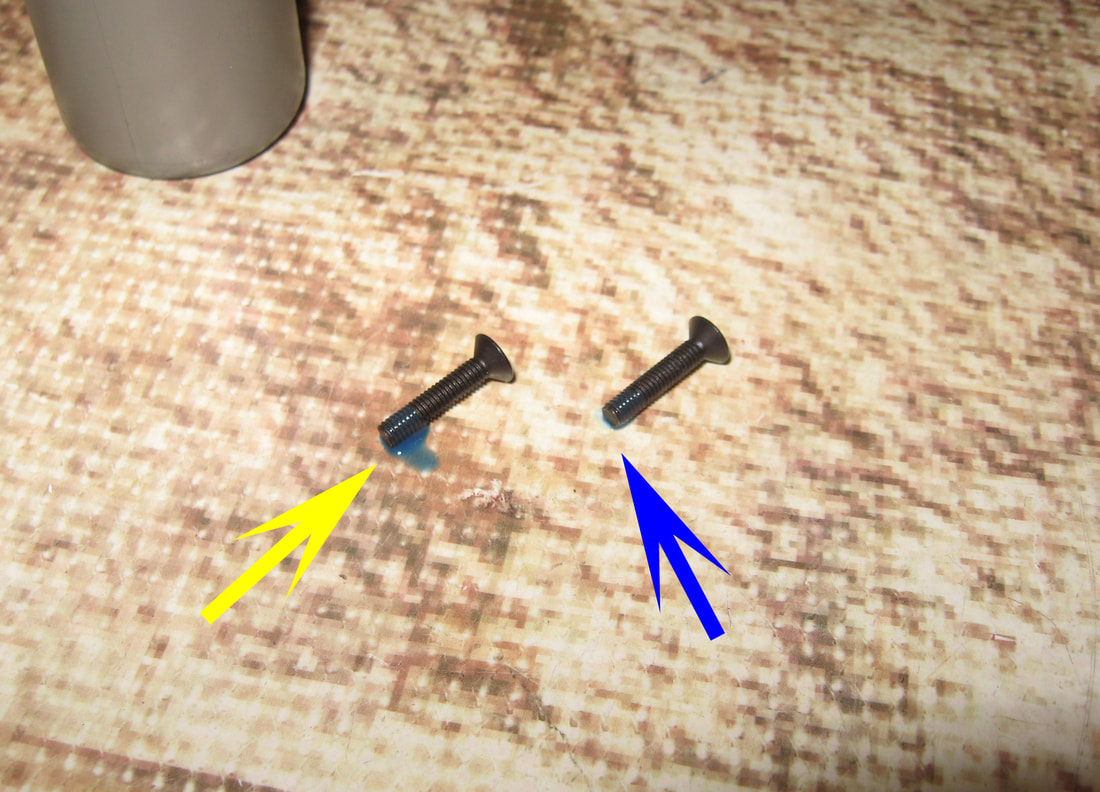

Second, ensure you are only using a small amount of liquid (Blue arrow). Consider also, if the screw is passing through, say a ball joint, the entire length does NOT need to be coated in gobs of thread lock (yellow arrow); only the mating surface (Blue arrow). Often, less is better for thread lock, but if the screw works itself loose, consider what you used last time and increase it.

0 Comments

Leave a Reply. |

AuthorMichael Rogers Archives

July 2022

Categories |

The best way to search for the part you need is by the manufacturer's part number. If you do not know the part number, please visit our Archive Page, or use a common term like, "Losi XX shock tower."

All prices are in USD. Copyright © 2011-2024 Valkyrie RC Motorsports LLC. All rights reserved. All product names, logos, and brands are property of their respective owners. All wording and photos on this site are the property of Valkyrie RC Motorsports LLC, and may not be used without prior written consent..

BBB current rating is A+.

BBB current rating is A+.

RSS Feed

RSS Feed