|

Suspension maintenance is key to a smooth race. Plastic ball cups should be inspected for fit and wear, also look for bent tie rods, as these can result in inconsistent handling. Pivot balls should be periodically replaced, as they do wear. If the same ball cup joint keeps popping off, it might not be the plastic that is worn.

0 Comments

Slotting a small groove into the center of your foam tire inserts will allow the tire carcass to lay flatter against the racing surface resulting in an increased tire patch. More tire patch equals more traction!

Use a paint marker to mark parts needing replacement. In this case, on race night, I stripped a screw in the steering arm. It was not bad enough to stop racing, but would need replacing ASAP. By marking it, I know what part I am dealing with at a later time, facilitating a time savings on tear down, and ordering parts.

Unfortunately, RC racing also means breaking parts, and fixing things. There is nothing more frustrating then a race night cut short by not having the correct spares on hand. You don't need to include the kitchen sink, but common sense will result in more track time, and less DNF the race day.

Recommendations:

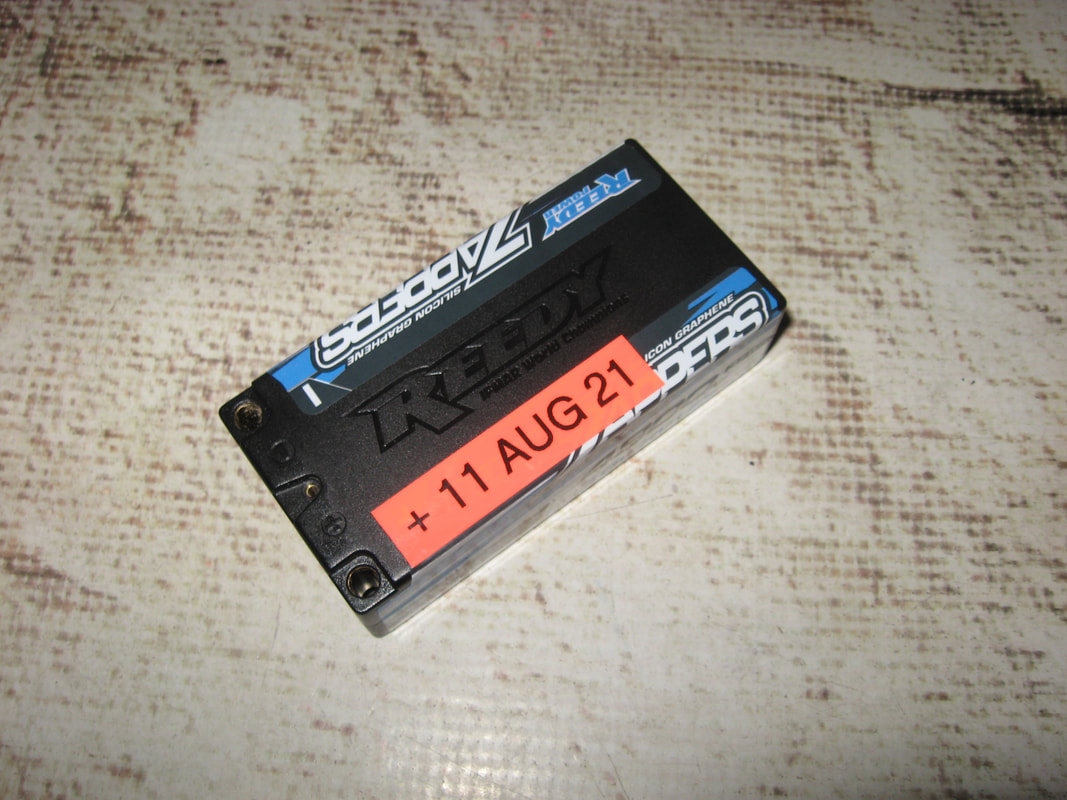

Each racing season, when I purchase new batteries, I always label them with the date of purchase. Later, this makes it easier to select batteries that may need culling from the race scene. In this case I have combined the label to also indicate polarity, making it easer to see.

When trimming masking during painting RC bodies, I was running into the long handle of the knife getting in the way. I used a rotary tool to cut the handle down. It is recommended to still have a long handled knife, but having a short one makes getting into tight spots a lot easier.

So, you snapped that new hex tool tip getting the above screw out of your car? Then you had to use a rotary tool to slot it, ruining that chassis in the process... I wonder why? The proper application of thread locking compound is not difficult, but it is easy to over do. First, ensure you are using the correctly rated thread compound. For most RC applications, "permanent" (often red), is almost never used. This is on par with spot welding, true the screw will never move, but removing it in the future for maintenance might prove impossible. For most RC applications, "temporary" (often blue) is used.

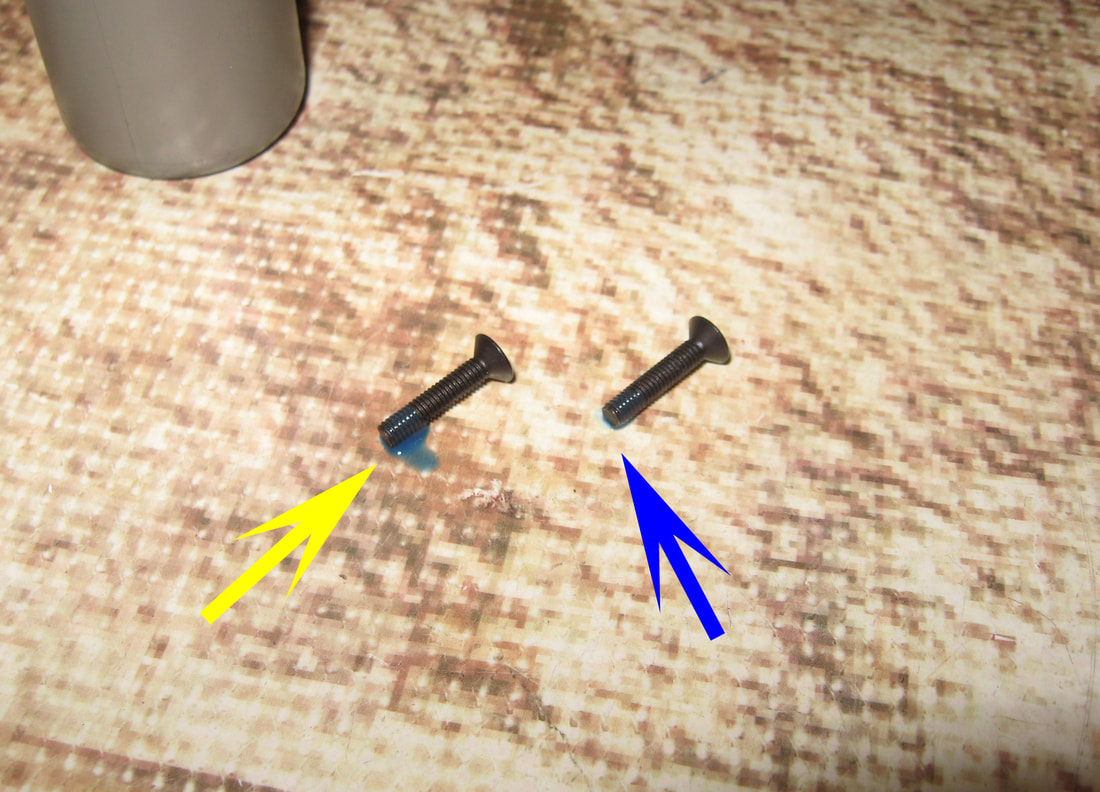

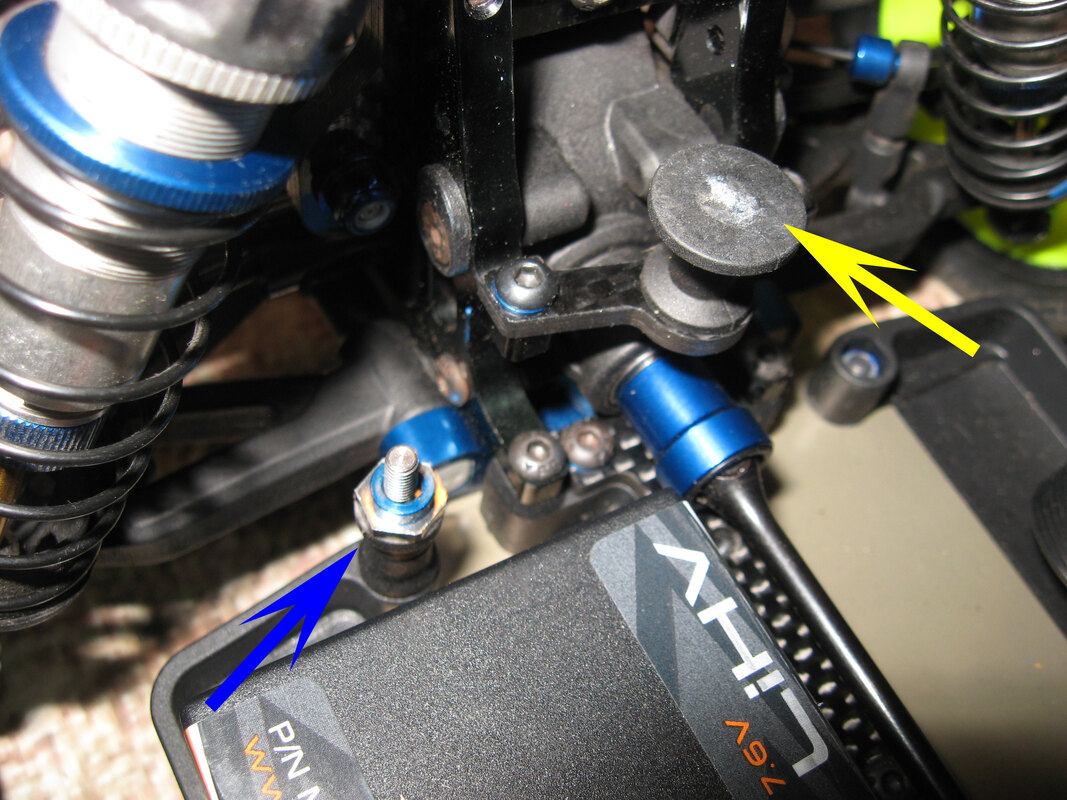

Second, ensure you are only using a small amount of liquid (Blue arrow). Consider also, if the screw is passing through, say a ball joint, the entire length does NOT need to be coated in gobs of thread lock (yellow arrow); only the mating surface (Blue arrow). Often, less is better for thread lock, but if the screw works itself loose, consider what you used last time and increase it. Yellow Arrow: If using hook-and-loop tape to secure your racing body, keep the original body posts, but remove the pin section. This allows the body to sit correctly, and is less likely to "drop" on a heavy impact.

Blue Arrow: AE instructions call for placing a shim, or cutting down the battery posts, to allow for differing battery heights. I moved the shim to the other side keeping the post at the stock length. This allows for faster adjustment to the battery post height for change-outs, as not all my packs are the same size. Just be careful to not lose the shims between uses. Racing is racing, no matter what platform. I recently obtained a 1/4" (6.35 mm) driver with a built in settable torque wrench, that is normally used for racing bike builds. When combined with MiP Allen hex tips this tool makes for an easy and repeatable assembly of RC cars and trucks. Unit works well on any metal hardware to metal contact. Metal to plastic contact takes some practice, and it is still possible to strip the plastic, but this is one tool I am having fun learning about.

|

AuthorMichael Rogers Archives

July 2022

Categories |

The best way to search for the part you need is by the manufacturer's part number. If you do not know the part number, please visit our Archive Page, or use a common term like, "Losi XX shock tower."

All prices are in USD. Copyright © 2011-2024 Valkyrie RC Motorsports LLC. All rights reserved. All product names, logos, and brands are property of their respective owners. All wording and photos on this site are the property of Valkyrie RC Motorsports LLC, and may not be used without prior written consent..

BBB current rating is A+.

BBB current rating is A+.

RSS Feed

RSS Feed